SHOP HACKS:

How To Add a Router Table Life To Your Table Saw without taking up any space

If you have a table saw and wanted a router table with a lift without taking up any more room in the shop, you'll absolutely love this article.

Basically, you'll be using the space inside the table saw extension rails.

You can add a router lift and not use up any extra space in your shop... and use the rip fence from the table saw on the router.

That area between the table saw rails is otherwise unused space.

So why not consolidate space a little... plus you'll spent way less on building this compared to buying a stand-alone router table!

Let's Take A Look At How It's Done:

Basically its two pieces of 3/4". One is MDF and the other is Birch.

First layer routered, and cut out. 3/4" MDF

Made a metal gasket to keep the leveling screws from digging into the wood over time.

Flushed in T Nuts into the top of the second layer ( 3/4 5 layer Plywood). These T nuts wont be seen and hold the dust collection system to the bottom of the table.

Good enough to lay flat under the top layer of the table.

The dust collector half assembled just to check fitment before I laminate the two layers of the table together.

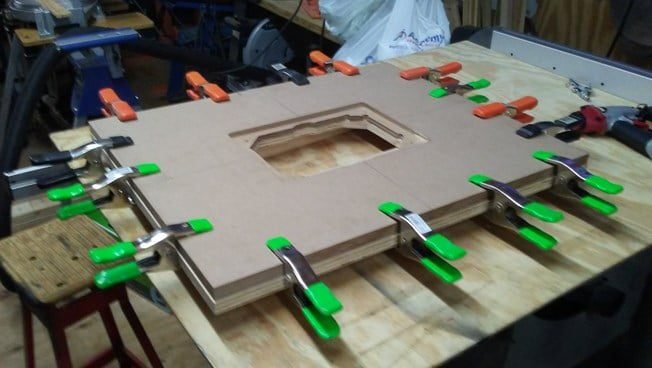

Wood glue, nail gun, and a ton of clamps. The two layers are laminated together.

Angle Iron bolted to the rail extensions of the table saw. Used carriage bolts. Drove them into the drilled holes for as slim a fit as possible. But it created a problem fitting the table into the rails without sitting on the head of the carriage bolts. No problem!

After some marking. Took a 3/4 router bit on a palm router. Made slots just wide and deep enough for the head of the carriage bolts to have clearance.

Shimmed up the table on both sides just a touch to be level with the rest of the table saw top. Then added the router lift.

I used 1.5" angle iron with a 1/8" wall to support the whole assembly to the rails of the table saw.

The router lift is the Incra Master Lift II. The router is a Porter Cable 890 series. 2 1/4 HP with adjustable speed.

There is a piece of thin gauge metal cut to fit in the recessed area of the table for the lift. It keeps the leveling screws for the lift from digging into the wood over time.

The Formica laminate is a writable surface with 1" square pattern covering it. Works as a scale, and also as a 22" x 27" erasable note pad.

It looks good, easy to slide your work pieces across, and to protect the top of the assembly from gashes and damage.

I choose the Formica laminate that has the one inch square block pattern. The surface is a writable surface that cleans back off super easy with windex or any glass cleaner.

So it have me a clean smooth surface. Also with the one inch block it works like a scale and I can write figures and stuff on it. Then clean it all off when done.

Want more details and more shop hacks like these? Get the Ultimate Small Shop guide