Diy Modern Outdoor Bench

Note: All projects performed following instructions found on this site are done at your own risk. Learn more

First of all, the construction of this modern outdoor bench is quite simple. It has a style that suits your farmhouse or the rural area you live in. In terms of durability, the screws we will use will overcome this.

Building a sitting bench can be both fun and budget-friendly. Read on for the plans and steps for how to make a sitting bench. You will sitting bench plans, dimensions, details and instructions here.

Review them carefully so you will be ready when it’s time to cut and organize the pieces.

Sitting bench building process starts with legs and side supports.

Hardwood or pressure-treated boards are a popular choice, as are cedar and cypress.

Pressure-treated timber is easy to stain, durable and budget-friendly.

1) Starts by checking the list of tools to use for your DIY sitting bench. After collecting the missing tools, focus on purchasing materials.

2) Measure and cut all the pieces and prepare them. Measure the length twice before doing your cuts. Make sure to label each one.

Tips: Drill pilot holes in wood pieces using a power drill for easy connections.

3) Follow the Project details for assembling the wood pieces.

4) We will use 1 1/2", 2 1/2" and 5" Screws.

5) You will secure use wood glue to the contact surface.

6) Fill any gaps and frame nail holes with wood putty.

7) Sand the entire Project with 150-220 grit or more sandpaper and dust pf before painting or staining your finished Project.

How to Build a Modern Outdoor Bench

Cut List:

A1 - 4 – 2 x 4 x 22″ legs 7'4''

B1-B2-B3 7 – 2 x 4 x 14 1/2″ right and left top, bottom and middle supports 8' 5 1/2''

C1 - 2 – 1 x 4 x 14 1/2″ horizontal support pieces between legs 2'5''

D1 - 2 – 2 x 4 x 48 1/2″ front and back support parts 8'1''

C2 - 12 – 1 x 4 x 17 1/2″ top boards 17' 6″

Total: 2x4x23'10 1/2''= (3 pieces) 2x4x8' , 1x4x19' 11''= (2 pieces) 1x4x10'

List of tools:

- Tape measure

- Jigsaw, miter saw, table saw

- Drill, nail gun

- Countersink drill bit

- Wood glue

- 2 1/2", 5" Screw.

- Sanding, air compressor

- Stain/preferred paint coating:

- Water-Based Pre-Stain Wood Conditioner

- Water-Based Wood Stain mixed: Desert Sand and Pure White

- Water-Based polyacrylic

Note: As an Amazon Associate, I earn from qualifying purchases.

Notes:

First, sand the wood with 150 grit or higher sandpaper to achieve a smooth, even surface before staining.

Thoroughly remove all dust from the wood by using a vacuum with a hose attachment, then wipe clean with a damp cloth.

Then wiping clean with a damp cloth. First, apply Pre-Stain Wood Conditioner to the boards.

Apply the Pre-Stain Wood Conditioner and allow it to penetrate the wood for just 1-5 minutes, then remove excess conditioner that has not soaked into the wood with a clean rag

Apply Water Based Wood Stain to all of the wood. You can the color Desert Sand mixed for 1 x 4 top boards and the color Pure White mixed for the legs. What I love about the water-based stain is

1) how easy clean-up is…

2) how little odor the stain has…

3) the colors. You can get everything from bold, colorful shades to neutral wood tones to light, creamy cottage and ocean-inspired stains.

Apply the stain using a foam brush, and allow it to penetrate the wood no longer than 3 minutes. It is very fast-drying, so work in small sections!

Wipe the wood with a clean cloth to remove any stain that has not soaked into the wood. Allow the stain to dry 24 hours before applying a protective finish.

Tip:

It will be easier to wear a pair of gloves while wiping the excess stain to keep our hands clean than to wash our hands.

After the stain has dried 24 hours, apply a thin coat of Water Based Polycrylic (I used the clear matte finish) using a brush. Allow to dry at least 2 hours, then sand with a very fine 220 grit sandpaper and remove all dust.

Apply a second and third coat, drying and sanding in between each layer. The wood will need 3 hours to dry before handling and 24 hours before it will be fully cured.

If you've ever used polyurethane on top of white paint and seen the yellow stains that appeared once the poly dried, you know how important it is to make sure you're using the right topcoat.

* If you wish, you can create different beautiful results with your own color choices. I prefer to use these colors mostly for coffee table. But beautiful colors will look good anywhere.

General Dimensions

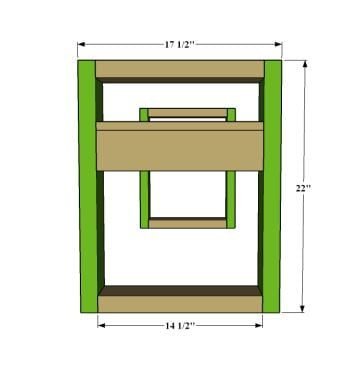

Side View:

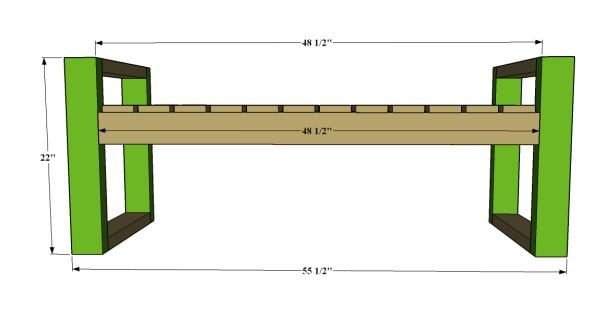

Front View:

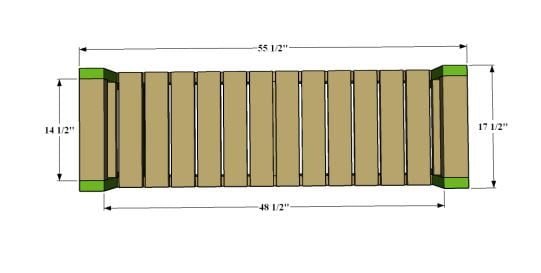

Top View:

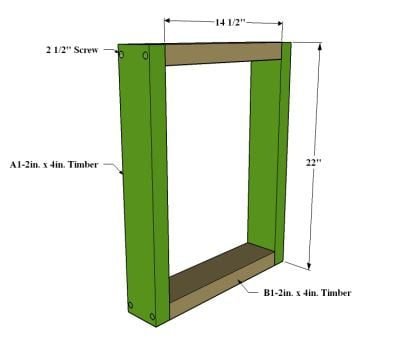

Bottom View:

Assembly Process:

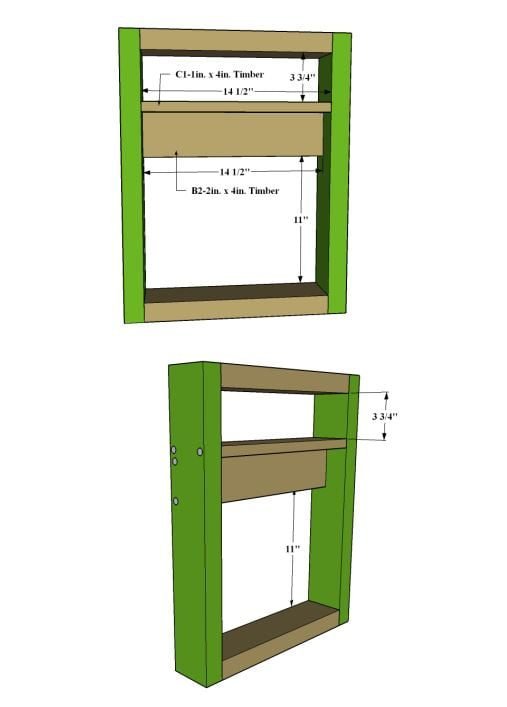

Step 1:

First, we glue the B1 parts to the lower and upper ends of the A1 legs and screw them from the outside after drying. We use 2 1/2" screws here. We glue the other foot to the end of the B1 pieces and screw it from the outside.

If you have enough experience and tools, you can screw in the B1 parts by drilling pocket holes. Set your pocket jig for 1 1/2 inch lumber, and make two pocket holes on either end of the shortest 14 1/2-inch lengths of wood.

With the pocket holes on the underside of the board, use 2 1/2-inch exterior kreg screws to attach the two 22-inch pieces of wood to either side of the three shorter 14 1/2-inch boards.

Step 2:

Now we measure and mark 3 3/4'' from the top piece B1 down. We glue the C1 piece horizontally just below the marked place and screw it from the outside. If you wish, you can also screw in using a krag jig by opening pocket holes as in the previous process.

Now we glue the B2 part to the lower outer part of the C1 part and screw it from the outside. In this and other screwing processes, you can screw in by drilling pocket holes as we did in the first process.

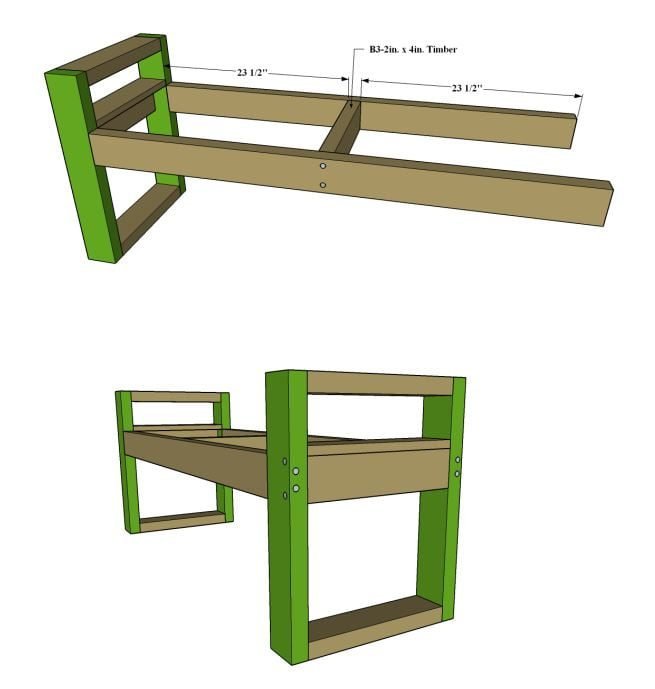

Step 3:

After completing the parts of these feet, we repeat the same operations once again and prepare the feet on the other side.

Step 4:

Now we glue the D1 front and rear support pieces so that they are aligned with the B2 piece near the middle.

After it dries, we screw it from the outside. Here, if we make the screws close to each other towards the middle, we prevent them from colliding with the other screws.

If we screw in from outside here, we will use 5'' screws.

Step 5:

Now we measure and mark a distance of 23 1/2'' inwards from the right and left of the D1 front and rear support pieces. We glue the B3 piece to the middle part.

Then, we glue and screw the other foot piece we have completed at the level of the B3 pieces so that it coincides with the end of the D1 pieces.

If you do the screwing process from the outside, we do it as in the picture below. We use 5'' screws for 3 1/2" thick pieces and 2 1/2'' screws for 1 1/2'' thick pieces.

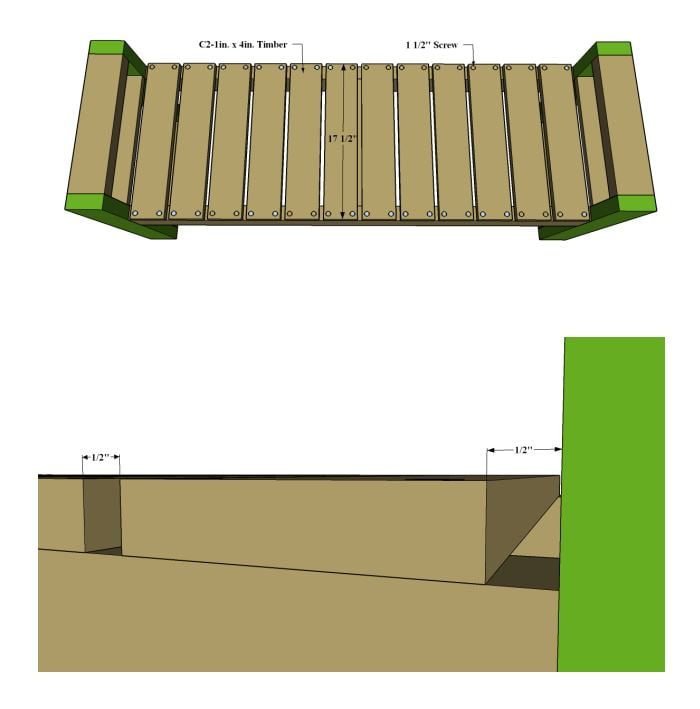

Step 6:

Now we glue the C1 top boards, leaving 1/2" space on the far right, left and middle parts. We use 1 1/2'' screws for the top boards.

Thus, we have completed our modern outdoor bench project!

Once the outdoor seating bench is done, you can make it comfy and cozy by adding a cushion.

The cushion can be purchased from a store, or you can also have cushions custom-made for the DIY patio seating bench.

It is not only simple and easy to build, but also looks attractive and fits well into nearly any space, style, and decor.

Remember: The best way to get building is to... get building!